VOC Recovery Apparatus / VOC Concentration systems Healthcare Products

VOC RECOVERY APPARATUS

K-Filter®

K-Filter® is a highly functional adsorbent with faster adsorption speed and fewer impurities than granular activated carbon.

“K-Filter®” is a registered trademark of TOYOBO in Japan for its VOC recovery equipment.

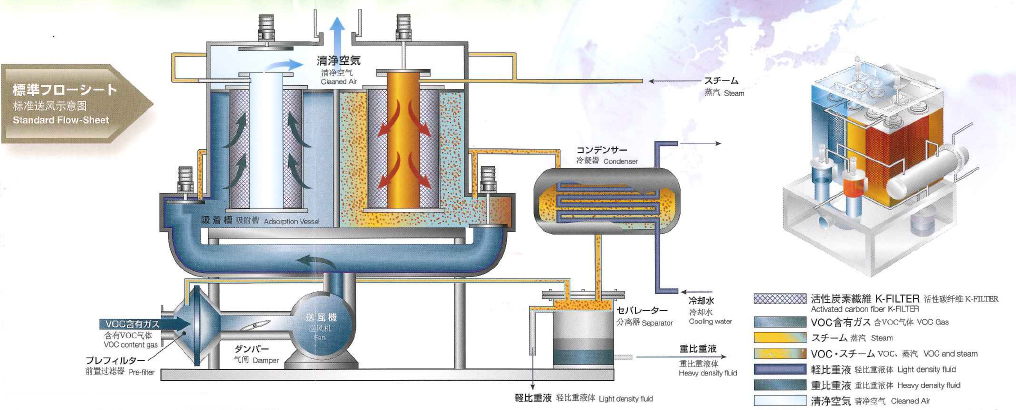

K-Filter® VOC Recovery Apparatus

It is a VOC recovery system with a built-in K-filter® that can recover VOC such as methylene chloride (lithium battery separator process, etc.) and ethyl acetate (dry lamination, adhesive process, etc.) with high efficiency and high purity. The K-Filter® VOC Recovery Apparatus is also capable of recovering solvents with better quality than granular activated carbon type recovery systems.

Features

Capable of recovering high quality solvents with low pyrolysis components from exhaust containing VOCs.

1 Superior VOC removal performance

K-Filter® has the excellent adsorption/desorption characteristics (high adsorption capacity and adsorption/desorption speed), and achieves higher removal performance and lower emission concentrations than conventional granular activated carbon.

2 High quality solvent recovery

The K-Filter® VOC recovery system, which brings out the excellent adsorption and desorption characteristics of the K-Filter®, lowers the thermal decomposition of solvents during desorption, and recovers high quality solvents. The recovered solvent is reused at many sites.

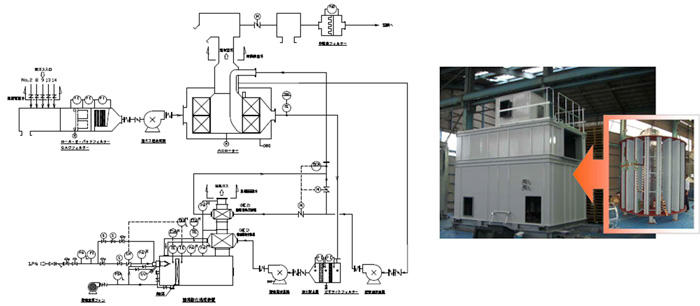

3 Lightweight, compact and flexible

The excellent adsorption/desorption performance of K-Filter® makes a lightweight and compact VOC recovery system possible. A wide range of unitized functions are available to flexibly propose equipment that meets customer needs.

4 Excellent safety

The system is designed to be used under normal pressure, so there is little heat buildup from VOC adsorption, resulting in excellent safety.

5 Applicable to various types of gas processing

In addition to general VOC gases, it is possible to remove and recover polymerizable monomers (styrene, vinyl acetate, vinyl chloride, etc.), as well as VOCs in industrial gases (carbon dioxide, hydrogen gas, hydrogen chloride).

Applications and Industries

Recovery of;

- ✓ Methylene chloride, Ethanol, IPA, etc. at Pharmaceutical plants and API plants

- ✓ HFO, HFE for precision cleaning and coating solvents

- ✓ IPA, PGME, etc. at Semiconductor and LCD factories

- ✓ Alcohol and Aroma chemicals in Food factories

- ✓ Perchloroethylene and trichloroethylene in Groundwater

- ✓ Any expensive solvents from other chemical plants

Processing performance: Recovery and removal (deodorization)

| Industry | Gas conditions | Processing performance | |||

|---|---|---|---|---|---|

| VOC | Air flow rate (m3/min) |

Inlet gas concentration (ppm)* |

Outlet gas concentration (ppm)* |

Removal efficiency (%) |

|

| Pharmaceutical, API | Methylene chloride | 20 | 9,900 | 16 | 99.8 |

| Toluene | 40 | 2,080 | 2 | 99.8 | |

| Chemical | Benzene, etc. | 60 | 2,760 | 6 | 99.8 |

| Styrene monomer | 480 | 100 | 1 | 99.0 | |

| Perchloroethylene | 960 | 2,600 | 6 | 99.8 | |

| Semiconductor, LCD | IPA, MEA, etc. | 50 | 650 | 3 | 99.5 |

| Butyl acetate, etc. | 60 | 700 | 5 | 99.3 | |

| IPA, etc. | 120 | 380 | 5 | 98.7 | |

| IPA, MEA, etc. | 280 | 60 | 1 | 98.4 | |

| Food, Fermentation | Ethanol | 50 | 840 | 10 | 99.8 |

| Cleaning | HFO | 30 | 150 | 1 | 99.3 |

VOC CONCENTRATION SYSTEM

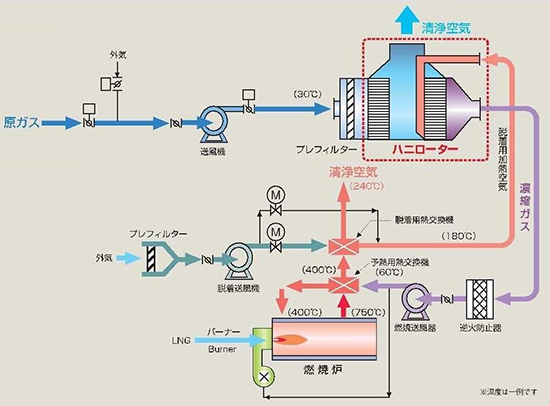

Ideal for treating exhaust gas emitted from coating machines with high air volume and low concentration.

Unique pre-treatment and high-performance zeolite honeycomb concentrates the low-concentration gases emitted from coating machine, etc., for economical combustion treatment. We offer the HONEYROTOR® VOC Concentration and Combustion System, which reduces VOC emissions from coating exhaust gas while saving energy.

HONEYROTOR® VOC Concentration System

The use of high performance zeolite honeycomb blocks makes it possible to process general coating exhaust as 35 times higher concentration, which makes it possible to downsize the combustion equipment in later stage.

The use of original cylinder type concentration system makes it easy to replace the honeycomb, and maintenance is extremely easy.

“HONEYROTOR®” is a registered trademark of TOYOBO in Japan for its VOC recovery equipment.

Features

The system incorporates a high-performance honeycomb adsorbent manufactured using a unique method, and employs a unique cylinder-type concentrator that enables economical treatment of gases containing VOCs.

1 Superior VOC removal performance

The use of honeycomb adsorbent with a high ratio of activated carbon and zeolite adsorbent manufactured by original unique method provides a high removal rate for a wide variety of VOCs.

2 Energy-saving operation

Because of the honeycomb structure, pressure loss is low even at a high wind speed of 2 m/s, and power consumption is small.

A high concentration rate of 20 times or more (concentration rate = air volume of raw gas / air volume of desorbed gas) is possible, and a significant reduction in running costs can be achieved by downsizing the combustion and recovery equipment.

3 Easy maintenance

Lightweight honeycomb blocks makes you easy to replace the honeycomb adsorbent without the need for heavy machinery.

Applications and Industries

Treatment of;

- ✓ Toluene, Xylene, etc. at Coating process

- ✓ IPA, PGME, etc. at Semiconductor and LCD factories

- ✓ Ethyl acetate, Methyl ethyl ketone, etc. at printing process

- ✓ Methylene chloride and Toluene in Pharmaceutical/API plants

- ✓ Benzene, Styrene, and Perchloroethylene at a Chemical plant

- ✓ Trichloroethylene at a Cleaning process

- ✓ Ethanol in Food factories

Processing performance

| Gas conditions | Processing performance | ||||

|---|---|---|---|---|---|

| VOC | Air flow rate (m3/min) |

Raw gas concentration (ppm)* |

Exhaust gas concentration (ppm)* |

Concentration rate (times) |

Removal efficiency (%) |

| Toluene, Xylene, etc. | 1,100 | 83 | 3 | 35 | 96 |

| 400 | 92 | 6 | 20 | 93 | |

| PGME, PGMEA, etc. | 1,650 | 150 | 1 | 22 | 99 |

| Ethyl acetate, etc. | 1,400 | 1,813 | 18 | 3 | 99 |

| Methylene chloride | 600 | 100 | 3 | 10 | 97 |

| Trichloroethylene | 200 | 50 | 2 | 12 | 96 |

| Ethanol, etc. | 1,200 | 493 | 15 | 7 | 97 |